Case Setting:

A plastic molding manufacturer needed a flexible feeding solution for a large family of plastic molded automotive clips.

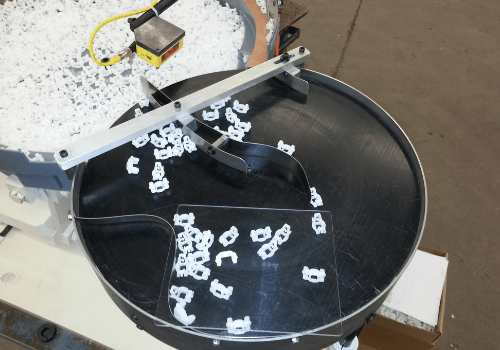

They wanted it to be able to feed their current family of 12 different clips that had many different geometric shapes as well as future parts that they would need to introduce to the system for upcoming model years.

The objective was to build a flexible feeding system so that the entire family of parts would be fed, 100% inspected and then assembled onto the product. This customer also wanted an easy method to change out the background to be able to run a rainbow of colors.

Result:

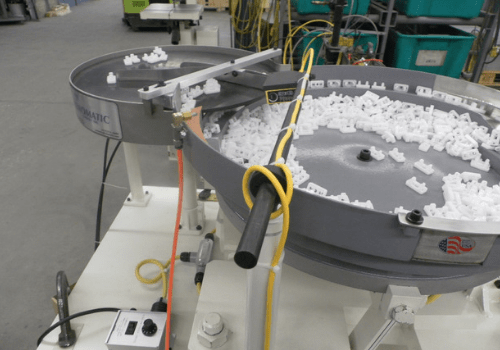

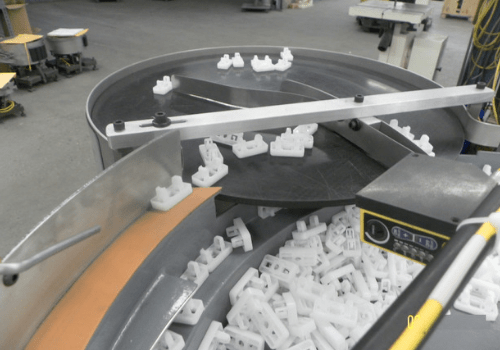

After discussions with the Vibromatic team, a solution soon followed. The solution was to make a disk type of flexible feeder that would combine a simple cascade vibratory feeder with an indexing disk.

This system would present the parts to the pick area for the robot. After the robot picked from the populated parts, the disk would index and repopulate the pick area with fresh parts for the robot to pick. Any of the parts not picked by the robot would be returned to the vibratory bowl to start over again. The disk was made of an easy to change out plastic disk so multiple color disks could be used to run the rainbow colors of clips.

Do you need a feeder system like this or another application? Contact us at sales@vibromatic.net for additional information.